TIMBERLITE™ ACCESS MAT

A TOUGH, LIGHTWEIGHT MAT FOR YOUR NEXT PROJECT.

The TIMBERLITE access mat is the ideal solution when you need a lightweight mat that’s still rugged enough for heavy equipment. Mixed hardwoods on the outside with pine in the middle timbers this mat is 50% lighter than traditional timber mats. See what the new TIMBERLITE mat can do for you.

SAFESTEPTM EPZ

GROUNDING GRATES

The next level of safety in transmission and distribution.

SAFESTEP EPZ Grounding Grates are all-in-one galvanized steel grates used to establish a safe equipotential bonded and grounded work zone. These highly durable grates can be used to create instant safety zones for applications including transmission line work, distribution work, renewable energy work, substation and mobile substation work.

See how simple and effective these grounding grates are to incorporate into your work site!

GET YAK TRAK

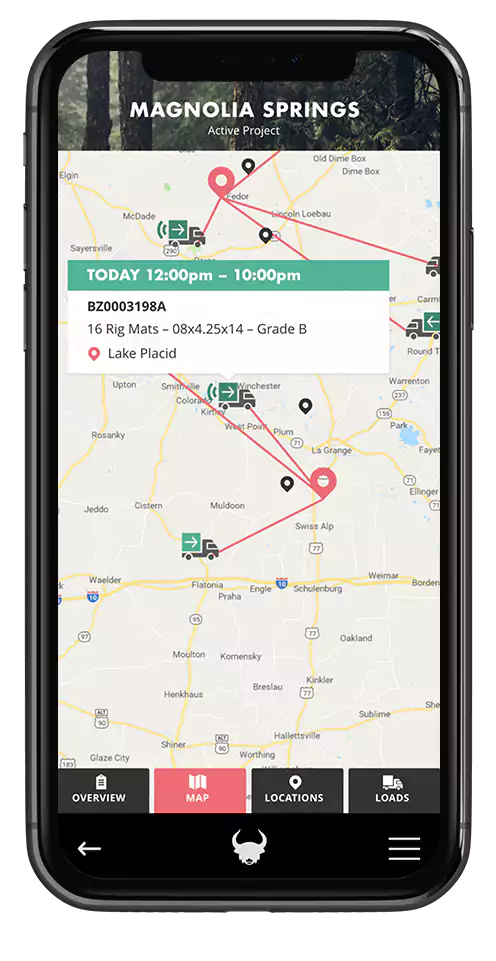

OUR CUSTOMER PORTAL MAKES MANAGING MATS EASY

YAK TRAK is a customer portal developed by YAK MAT. Easily request a quote directly from the portal, select appropriate mats from the digital product catalog, and track the status of your mat deliveries and pick ups in YAK TRAK.

YAK TRAK can be accessed on either PC or Mac computers at www.yaktrak.com.

Android or iOS users should download the YAK TRAK app to manage your mat projects while in the field or on the go.

THE LEADER

IN ACCESS SOLUTIONS

YAK MAT provides temporary road mat installation services for all areas of the energy industry including midstream, upstream, downstream, transmission and distribution, and more. No matter your industry or the size of your project, we can provide the right solution to ensure your project runs efficiently. For example, the use of temporary road mats can help upstream energy construction projects by creating roadways that may not exist in remote locations. For transmission and distribution infrastructure projects, our products allow large-scale machinery to be deployed without concern for the stability of the ground underneath it. Ground protection mats also can help crews across all sectors improve their sustainability by reducing the impact their actions have on wetlands and other ecologically sensitive areas. Our expertise, coupled with extensive inventory located throughout the country, means we can help you find the exact product to fit your needs no matter what they are.

SELECT YOUR INDUSTRY

1 MILLION MATS

A large portion of access mat cost is the freight expense to your project. Because we have more inventory yards than anyone in the industry, YAK MAT reduces transport costs and time and ensures unmatched inventory availability.